A Closer Look at CAD/CAM Technology in Digital Dentures

Technological breakthroughs have opened the door for seismic shifts in patient care and treatment options in the dynamic field of dentistry. The introduction of Digital dentures is one of these advancements that has permanently changed the industry. The use of Digital dentures has completely changed how dentures are created, manufactured, and experienced by patients. This is because to the integration of CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) technology.

In this blog, the team at Ottawa South Denture Clinic would like to examine the significant influence of CAD/CAM technology on the production of Digital dentures.

How CAD/CAM Technology is Used in Making Digital Dentures

The creation of Digital dentures relies heavily on CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) technology. Using it in the procedure involves the following:

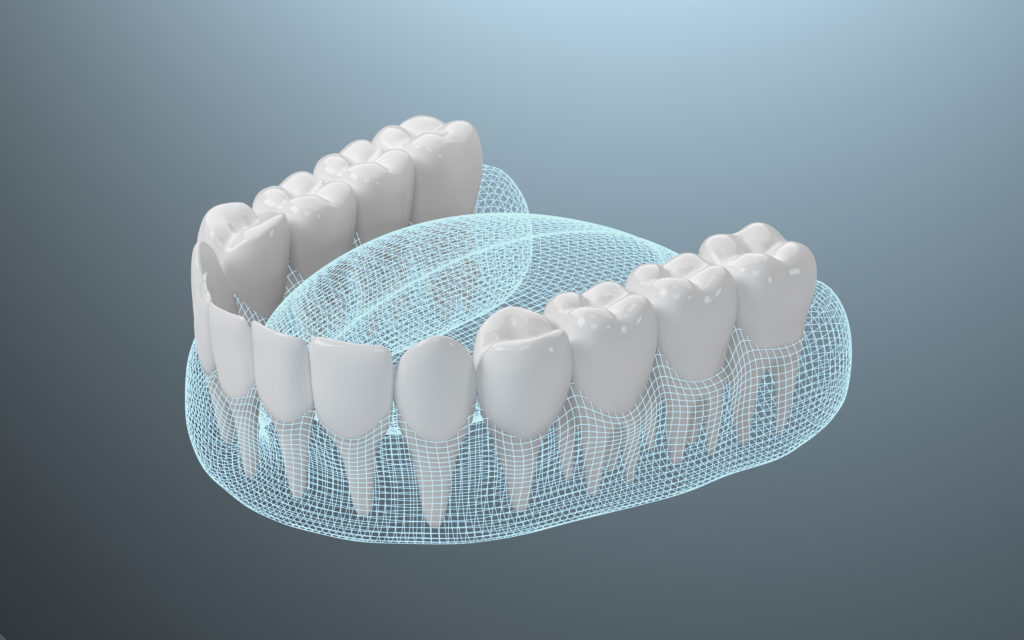

Digital Impression: A Digital image of the patient’s mouth often serves as the process’s first step. An intraoral scanner takes a 3D picture of the patient’s teeth and surrounding tissues instead of taking a standard imprint using dental putty. The basis for the Digital denture design is this digital impression.

CAD Design: Using CAD software, a virtual 3D model of the patient’s oral anatomy is made once a digital impression has been taken. Dental technicians can work with this model to properly construct the dentures to the patient’s requirements. To achieve the greatest fit and looks, they can adjust elements like tooth form, size, and placement.

Biomechanical Analysis: CAD software may also carry out biomechanical analysis to make sure the patient’s dentures will work properly. This entails making sure the occlusion (bite) is correct and that the dentures won’t be uncomfortable or interfere with your ability to talk and chew.

Material Selection: Using CAD/CAM technology, one may choose the best materials for dentures. Strength, durability, and aesthetic qualities vary across different materials. The selection of material is based on the requirements and preferences of the patient.

CAM Manufacturing: The use of CAM technology for production follows the completion of the digital design. CAM systems employ computerized design to direct the creation of dentures. This could entail conventional casting, milling, or 3D printing, among other production processes.

Quality Control: To make sure that the finished product fulfills the required criteria, CAD/CAM systems frequently include quality control techniques. This may involve doing inspections on the manufacturing process’ accuracy and precision.

Fit and Adjustment: After being created, the Digital dentures can be adjusted and fitted to the patient’s mouth. The dentures may be precisely modified using CAD/CAM technology if improvements are required for greater comfort or fit.

Final Polishing and Aesthetics: CAD/CAM technology may also help with the final polishing and colour matching of the dentures to make them look more natural and aesthetically acceptable.

Impact of CAD/CAM Technology on Digital Dentures

The area of Digital dentures has been significantly impacted by CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) technology, which has revolutionized how dentures are created, produced, and given to patients. Here are a few significant effects:

Accuracy and Precision: CAD/CAM technology enables incredibly accurate digital impressions and design. Dentures made with this level of accuracy fit and work better in the patient’s mouth. Additionally, the precision lessens the need for numerous modifications, saving time and money.

Customisation: A significant degree of customisation is possible with CAD/CAM. Dentures can be custom made to fit each patient’s individual oral anatomy, including the form, size, and arrangement of their teeth as well as the curves of their gums. This personalization enhances the patient’s comfort and attractiveness.

Patient Comfort: When compared to traditional putty impressions, digital impressions are often more comfortable for patients. Furthermore, dentures created using CAD/CAM technology frequently fit better, resulting in less pain, tender places, and the requirement for adhesives.

Efficiency: The digital workflow of CAD/CAM technology speeds the denture-making procedure. It takes little time to create digital impressions, and CAD software expedites the design process. CAM manufacturing techniques, like as 3D printing and milling, are effective and can make dentures more quickly than conventional techniques.

Quality Control: By incorporating quality control procedures, CAD/CAM technologies lessen the possibility of manufacturing mistakes in dentures. This makes that the finished product satisfies the necessary requirements and quality standards.

Reduced Waste: Compared to conventional processes, which frequently include hand sculpting and casting, the creation of dentures using digital technology produces less waste. With little material waste, CAD/CAM techniques create dentures.

Cost-Effectiveness: Although CAD/CAM equipment and training may require an initial investment, the technology can eventually result in cost savings. Lower manufacturing costs can be achieved through reducing the number of changes, cutting down on material waste, and improving productivity.

Improved Communication: CAD/CAM technology makes it easier for dental professionals and dental labs to communicate. Digital files make it simple to collaborate and make changes, improving the likelihood that the final denture will satisfy the patient’s needs.

Aesthetics: The use of CAD/CAM technology enables rigorous attention to detail in the design of dentures. Dental practitioners can make dentures that seem real by matching the shade and contour of the patient’s natural teeth.

Patient Satisfaction: With Digital dentures, patients report feeling more satisfied because of the superior fit, enhanced aesthetics, and less pain. Patients are more likely to be pleased with the outcomes, which encourages good recommendations from others.

Ottawa South Denture Clinic – Top-Rated Digital Denture Clinic

Digital dentures have revolutionized the patient experience by providing a cozy, individualized solution that meets each person’s particular demands. The era of uneasy imprints and painful prostheses is over. Instead, patients may now take use of dentures that fit perfectly, enhance their appearance, and raise their quality of life as a whole. Additionally, the benefits of CAD/CAM technology in Digital dentures go beyond those of a single patient. Streamlined processes, less material waste, and improved communication are advantageous to dental practitioners and labs. These benefits help with cost-effectiveness in the long run while also enhancing efficiency.

Are you prepared to experience the unmatched comfort and perfection of dentistry’s future? Please contact us at Ottawa South Denture Clinic! Discover the life-changing advantages of Digital dentures at our cutting-edge clinic, which are precisely produced using CAD/CAM technology. Say good-bye to uncomfortable dentures and welcome to a personalized, cozy, and attractive grin. Make an appointment with Ottawa South Denture Clinic right now to book your consultation and begin the journey to a happier, more self-assured you.